I have had great success with my E3D V6 bowden clone on my Anet A8. I printed 3 separate parts from thingiverse.

I use the Tech2C Bowden V2 for the mount and cooling fan. Unfortunately the carriage slider is made for a Prusa i3 which does not work with the Anet A8. The Prusa uses 45 mm spacing between the 2 8 mm linear rods of the x carriage while the Anet uses 46 mm spacing. So I used this 3 bearing x carriage by Alandwells. I started by using the stock A8 extruder which already accepts the 4 mm push fitting that came with the E3D V6 bowden kit I bought from amazon.

I have a need to start printing TPU filament on my Anet A8 that has been converted to a bowden setup. The setup I have prints PLA like a champ. Unfortunately it does not work well with TPU filament. So I have decided to convert back to a semi direct E3D V6 setup.

To prepare for the semi direct feed extruder I had to come up with a new cooling fan system. I remixed a fang fan duct from for a CR10 by Ozfunghi. I also have to incorporate an extuder that will work with flexible filaments. I chose to incorporate a remix of bowden extruder for flexible filaments by betamax that uses the MK7 extruder gear.

The picture below is my printer. In the photo I have the bowden setup described above and the fang cooling fan setup. I was printing a part to test the fang cooling fan.

I'll give an update when everything is printed and installed.

I use the Tech2C Bowden V2 for the mount and cooling fan. Unfortunately the carriage slider is made for a Prusa i3 which does not work with the Anet A8. The Prusa uses 45 mm spacing between the 2 8 mm linear rods of the x carriage while the Anet uses 46 mm spacing. So I used this 3 bearing x carriage by Alandwells. I started by using the stock A8 extruder which already accepts the 4 mm push fitting that came with the E3D V6 bowden kit I bought from amazon.

I have a need to start printing TPU filament on my Anet A8 that has been converted to a bowden setup. The setup I have prints PLA like a champ. Unfortunately it does not work well with TPU filament. So I have decided to convert back to a semi direct E3D V6 setup.

To prepare for the semi direct feed extruder I had to come up with a new cooling fan system. I remixed a fang fan duct from for a CR10 by Ozfunghi. I also have to incorporate an extuder that will work with flexible filaments. I chose to incorporate a remix of bowden extruder for flexible filaments by betamax that uses the MK7 extruder gear.

The picture below is my printer. In the photo I have the bowden setup described above and the fang cooling fan setup. I was printing a part to test the fang cooling fan.

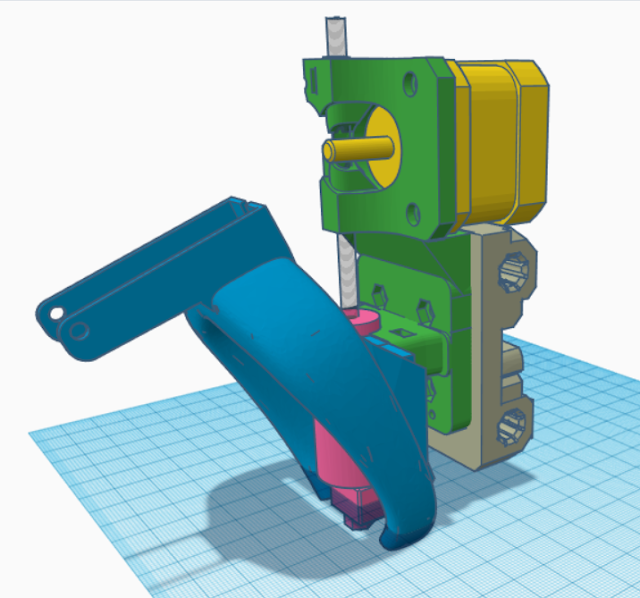

Here is a screen shot of what I have designed in Tinkercad.

Comments

Post a Comment